Fiber Safety

1. Intro

1.1 Description

Although fiber is a relatively safe material to work with, there are some hazards to be aware of. These hazards can be particularly troublesome since bare fiber is microscopic and transparent; it is nearly impossible to detect if you lose track of your scraps.

They come in two forms:

- fiber scrap

- fiber shard

1.2 Details

There are some details to keep in mind while reading this page:

- The fiber cable refers to the glass fiber, cladded and wrapped by both inner and outer jackets.

- Bare fiber refers to the glass core that is left after stipping the outer and inner jackets as well as the cladding.

- The cable is spooled in the package; the curvature is a hazard as the cable will bend back quickly when straightened out.

- Bare fiber is extremely fragile.

- Positioning the fiber on the cleaver or splicer is a delicate operation. The fiber is likely to poke a hard surface and bend, leading to breakage. If not careful when unclamping the cable, it will jump out of the tool and back into shape as mentioned in (3).

- Once fiber gets in your body, it may never leave as it neither decays or get broken down by the immune system.

- Using a microscope to locate fiber is only possible on skin and is extremely challenging due to the scale, the elasticity of skin, and uneven surface of the skin.

- The hazards can also affect others who are currently in the space or will be in the future.

2. Fiber Scrap

2.1 Description:

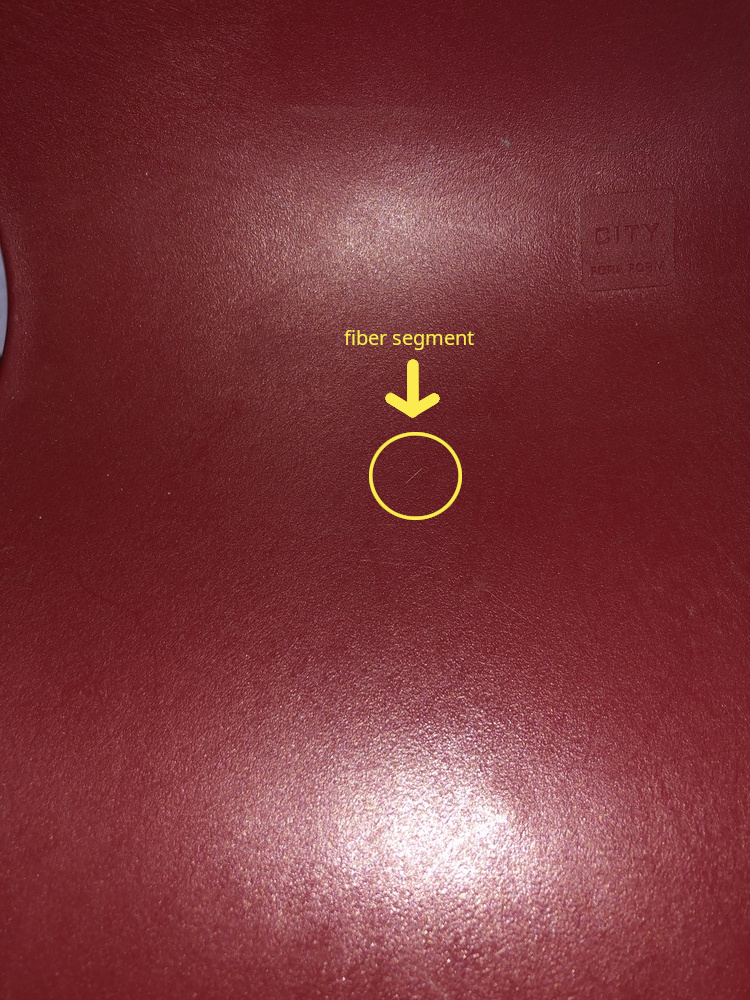

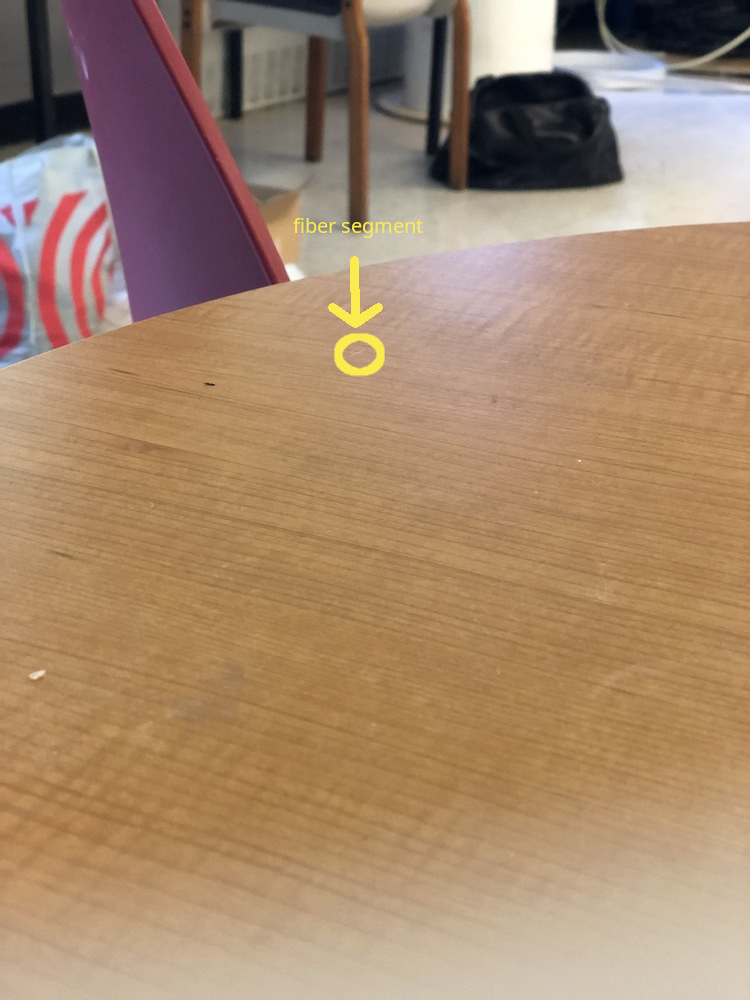

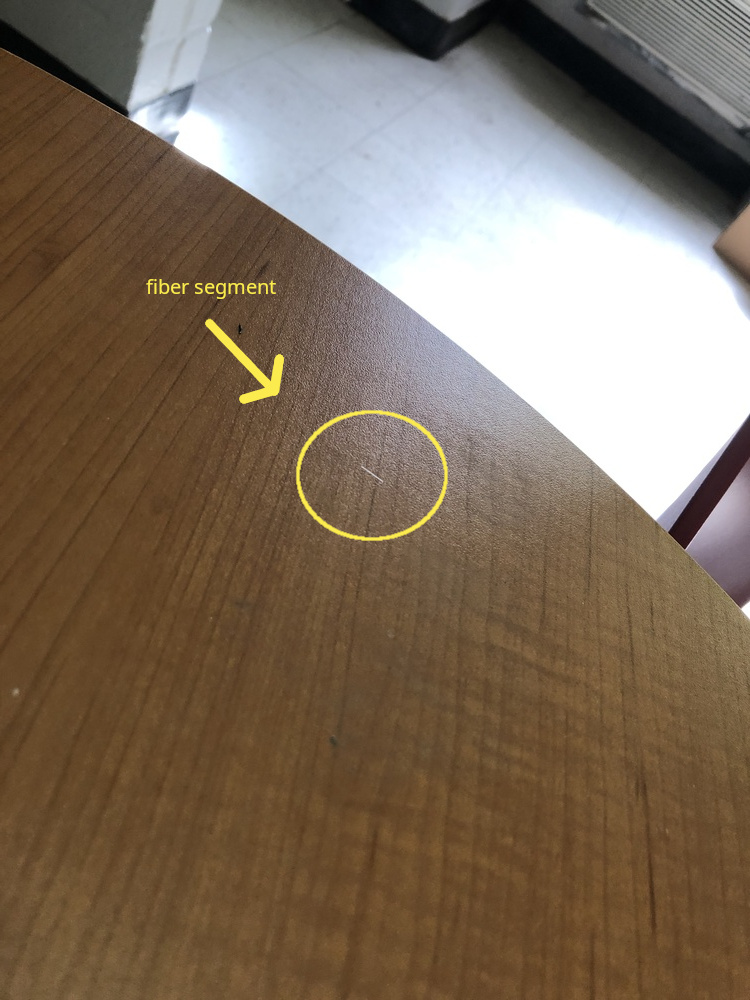

A piece of fiber scrap is a segment of bare fiber which gets created while cleaving or accidentally breaking bare fiber. Scraps can break down into smaller segments or into shards. They are the easier pieces to keep track of due to their length. If a scrap disapears, shining a flash light at different angles on a surface will produce a segment shaped glimmer if it hits a scrap.

As shown in the pictures bellow, the amount of light and angle at which it hits the scrap affects the visibility. Note that these are two different pieces of scrap, which were found by closely inspecting the surfaces using a flashlight.

2.2 Hazards:

There are two ways in which scraps are hazardous; pricking and snapping.

-

pricking

How:

Pricking can occur when the cable flicks back into shape and hits exposed skin, when attempting to grab scraps with bare hands, or when touching/sitting on a surface which happens to have unseen scrap(s) on it.

Consequence:

Pricking can lodge splinter or shards bellow the surface of the skin.

Mitigation:

PPE (rubber gloves, eye protection with side shields, coveralls, dark mat work area). -

snapping

How:

Snapping can either occur when the cable flicks back into shape or when bending the fiber too far when positioning the fiber on the cleaver or splicer.

Consequence:

Snapping can send both a scrap and shards flying; These can land on food, in the eyes, on the surface of the skin, and shards can be inhaled.

Mitigation:

No food or beavarages around, PPE (rubber gloves, eye protection with side shields, coveralls, dark mat work area, plexiglass sheet).

2.3 Potential consequences

-

Ingesting scraps can cause internal hemoraging.

-

Lodging scrap or shards bellow the skin will cause discomfort, and potentially cause infection.

-

Shards' potential consequences are addressed bellow.

3. Fiber Shards

3.1 Description:

Fiber shards are microscopic glass shrads; similar to fiberglass dust. They are nearly impossible to track due to their size; the smallest shards can be measured in micrometers (1 micrometer is 1/1000th of a millimeter).

3.2 Hazards:

- dispersion

How:

Due to their size, the smallest shards can be carried by air currents.

Consequence:

Shards can be inhaled, land on skin, eyes, clothes, food/beverage or nearby surface to be picked up later.

Mitigation:

The space needs to be well ventilated, no food or beavarages around, PPE (rubber gloves, eye protection (side shields), coveralls, dark mat work area, respirator designed for the hazard).

2.3 Potential consequences

-

Ingestion can cause inflamation and potentially internal hemoraging.

-

Shards in the eyes or on the surface of the skin can cause inflamation.

-

The Washington Department of Health claims that 1) Depending on the shards' size and shape, they may be biopersistant, 2) on the short term, inhaled shards will cause inflamation in the airways and exacerbate existing issues, and 3) on the long term, unlike for asbestos, lung disease rates of workers chronically exposed to fiberglass dust are "not consistently different from what is found in the United States general population". This source claims that this is due to the different structures of asbestos and fiberglass; that they break differently.

4. DOS AND DON'TS

DO:

- Clean up any cluter before handling fiber.

- Use PPE (e.g. eye protection or face visor, disposable coveralls, black rubber gloves ...).

- Wear dark clothes to spot scraps/shards more easily.

- Handle fiber over black, non-reflective surface.

- Handle fiber in a well lit and ventilated area.

- Pick up fiber fragments/scraps with tweezers (preferably rubber coated for better grip and lower risk of breakage).

- Frequently clean surfaces with adhesive tape (NOT a brush) to catch stray pieces. FOLD THE TAPE ONTO ITSELF BEFORE DISPOSING IT.

- Use tape to remove fiber coating from 3rd hole of stripping tool (since it may contain shards).

- Wash your hands after handling fiber.

- Dispose of fiber fragments and scraps in a suitable container; tape used to catch scapes should also go in that container.

- Follow systematic cleaning routine for your work area and all the equipment to avoid leaving scraps or shards behind.

DON'T:

- Touch fiber with bare hands.

- Touch your face after handling fiber.

- Blow dust or scaps off of a cleaver or fusion splicer, or any surface that looks dusty.

- Throw stripped material on the ground (stripping the coating can create shards).

- Look directly into plugged fiber to try to see lazer or infrared light ( infrared is invisible anyways).

- Eat or drink around fiber.

- If the segment is not visible, move your head around the cleaver or use a flashlight to make the glass shine; it may be on the top pad of the cleaver. DO NOT PICK UP THE CLEAVER AND FLIP IT UPSIDE DOWN; ESPECIALLY NOT ERRATICALLY. THERE IS NO REASON TO DO SO AND ONLY MAKES IT HARDER TO FIND THE SCRAP AS IT MAY FALL OFF.

5. RECAP

Hazard origins

Cleaving

-> scrap

-> shards

Cutting cable

-> shards

Snapping scrap

-> scrap

-> shards

Stripping jacket/cladding

-> shards

Hazards

Scrap

-> pricking

-> ingestion

Shards

-> inhalation

-> ingestion

-> skin, eye contact

Potential Health Consequences

Ingestion -> inflamation, internal hemorage

Inhalation -> airway inflamation

Pricking -> infection

Skin, eye contact -> inflamation

Bonus

Although risks are low for a few installs, over the long run, some installers may want to take more precautions. An extremely safe setup for the most risk averse of installers would be a DIY fume extractor. This setup is compact and mitigates all of the hazards mentioned in the previous sections.

The plexiglass walls contain any dust in a small area, the gloves protect the installer's skin and clothes, and the negative presure fan ensures proper ventilation. In addition, hooks and magnets can be used to keep some tools organized and permanently inside the container (e.g. stripping tool, tzeezers, alcohol pads...). In order to perform a splice near the ceiling, some mechanism needs to be used to strap the container atop a ladder (unless the installer considers a baker scaffolding affordable and convenient)

Equipment list:

- fume extractor ( < $200)

- 6 18*24 acrylic sheets + acrylic cement + small hinges OR large, clear plastic box (plastic box may not be as practical as custom acrylic box)

- 4 inch hole saw

- 4 inch pvc pipe

- plastic epoxy

- 2 worm clamps (for the gloves on the extractor)

- gooseneck arms with aligator clips

- nonslip pads

- arm-length gloves

- ventilation ( < $100)

- vaccum/fan with ~40ft 4 inch vent hose

- 4 worm clamps (2 for window adaptor to fan, 2 for fan to extractor)

- portable ac window adapter